The heat treating of metals and other materials is a crucial step in the production process, so the equipment used to anneal, temper, or sinter raw materials should be both efficient and adaptable. Adding a conveyor system can help manufacturers streamline processes, reduce costs and save time, and there are several ways this can be accomplished. Pneumatic and vacuum conveyors have been developed for certain niche applications, but the choice in most situations that involve exposure to high temperatures will boil down to a system that uses either a mesh belt or a series of rollers.

In this article, we will talk about the advantages of both options. As with so many manufacturing technologies, your application determines the equipment selection.

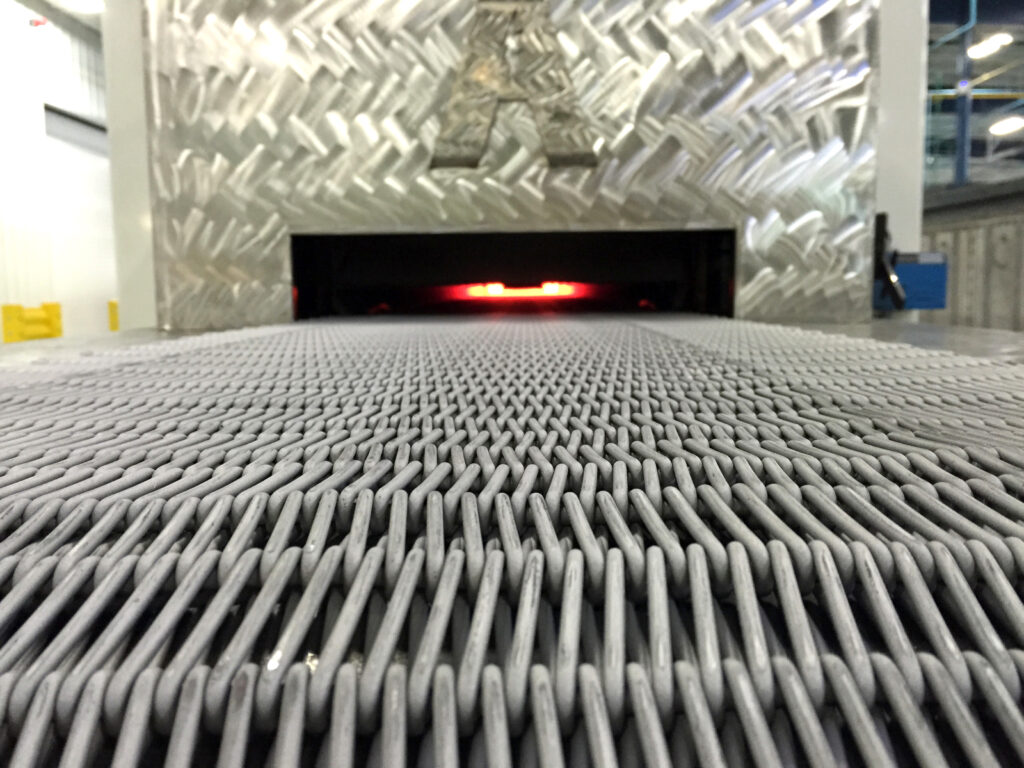

Mesh Belts for Industrial Furnaces

Mesh belts are a popular solution because they offer several benefits and are suitable for heat-treatment applications, including annealing, stress relieving, tempering and hardening. They can also tolerate temperatures in excess of 1000 degrees Fahrenheit.

Advantages of Furnace Mesh Belts

This kind of system is extremely versatile because it can convey material through quenching tanks as well as heating chambers. They can also be exposed to furnace atmospheres ranging from pure hydrogen to air. They can also withstand sulfidation, nitriding, carburization, and oxidation. Mesh belts are suitable for so many heat-treating processes because they can be used in environments with dew points below -100 degrees Fahrenheit and above +100 degrees Fahrenheit and in temperatures ranging from near ambient to over 1000 degrees Fahrenheit.

Maximum Energy Efficiency and Continuous Throughput

Continuous output is the chief benefit of any furnace conveyor system, and mesh belts are an energy-efficient tool for meeting production goals while maintaining the quality of the end product. This is primarily because the open mesh design allows heat to be transferred to the parts efficiently. Digital monitoring and control systems can reduce energy waste even further by keeping temperatures, atmospheres, and belt speed within proper parameters. These systems can be operated either manually or automatically.

Long Service Life

The mesh belts used on furnace conveyor systems are extremely durable. They are engineered to withstand exposure to extreme environments, and they can provide years of reliable service. A mesh design provides strength while keeping weight to a minimum, and reversing or flipping belts at regular intervals can prevent camber and add years of service life.

Easy Maintenance

Because a mesh belt has a more open fabric than a solid belt, it will be easier to inspect, maintain, and repair than other options. Manufacturers can keep their maintenance and repair costs to a minimum by choosing belts made with alloys and weaves suitable for their furnace applications and watching out for signs of distortion or wear. Belts should be cleaned regularly to remove contaminants and debris, and they should be supported evenly along the length of the furnace.

Tips for Proper Care of Mesh Belts

A furnace mesh belt is made of a series of smaller, interconnected components that make a single moving piece of equipment. As a result, uneven loading or misalignment of the belt can cause cumulative pressure and tension. Most problems with mesh belt conveyor systems are caused by overloading, misuse, or neglect, which can all be addressed with training and more rigorous maintenance and repair protocols. Loads should be distributed evenly to avoid camber and distortion, and belt tension should be checked on a regular basis. Mesh belt conveyor systems should also be inspected by a manufacturer’s representative at least once a year.

Roller Belts for Furnaces

Another common method of conveyance is the roller belt. Roller belts feature a series of independently turning tubular rollers assembled in a fixed frame. This creates a smooth and continuous surface for parts to travel across.

Advantages of Roller Belts

Installing a furnace with a roller system can be a faster process than installing a mesh belt because most of the assembly is done at the furnace manufacturer’s facility. Pre-assembled sections can then be transported to the customer’s site and easily moved into place. They are then welded and bolted together by factory trained professionals.

Good for Heavy Loading Applications

Furnace rollers are most commonly used when processes require moving heavy materials because the rollers turn independently with low friction. Rollers allow trays and individual items to move smoothly and without being pushed along by another tray or object.

Unlike a mesh belt, rollers are not susceptible to cumulative pressure or stress because they operate independently. This means they are a good choice for moving heavy components over longer distances.

Rollers Offer Flexibility

Depending on the application, rollers can operate as a unit with each moving at the same speed and direction, or they can be run individually. Because it’s possible for individual rollers to turn at different speeds, in reverse, or even stopped or set to oscillate, it’s possible to create very precise patterns of movement through the furnace such as moving more slowly through a muffle section, or pausing in a steam chamber for a set period of time.

Rollers also have long service lives because they remain in the same temperature zone at all times, which means that they are not subjected to the thermal cycling that can cause premature wear in belts or other conveyor systems.

Choosing the Right Conveyor for Your Furnace

When it comes to selecting the best conveyor system, your application is the determining factor. Both mesh belts and rollers have advantages in certain situations. There really is no one-size-fits-all conveyance system for all applications.

Considerations for Mesh Belts vs. Rollers

When making the decision between a mesh belt conveyor furnace and one that comes with rollers, manufacturers and metallurgical facilities should consider the following:

- Application: What type of thermal processes will the material undergo, including temperatures and time elapsed in the furnace?

- Materials: What are the characteristics of the material that will be conveyed, such as part weight and dimensions?

- Footprint: How much space is available for the furnace and its conveyor system?

- Operation: What volume of parts must be processed and at what speed?

- Environment: Will environmental factors like high humidity, corrosive gases, or flammable atmospheres influence the decision?

- Cost: What is the budget for the furnace?

Operating Temperature of Your Furnace

The operating temperature of the furnace is an important consideration. Temperature is a particular concern for mesh belts, which can become brittle over time when exposed to high temperatures. Stress-relief procedures are recommended when furnaces operate at temperatures below 1650 degrees Fahrenheit. This usually involves maintaining the belt at a temperature 50 degrees Fahrenheit higher than the usual operating temperature for an hour. When furnaces operate at higher temperatures, stress relief should be performed for at least two hours.

Process Requirements of the Belt

Process requirements are often the deciding factor when choosing a furnace conveyor system. For instance, if processes require material to be moved at a constant conveyor speed, a system that relies on mesh belts could provide a relatively simple and inexpensive solution. On the other hand, if your operations require heavy loads or a combination of different speeds of movement through the furnace, a roller system may be more appropriate.

Account for Belt Tension and Thermal Expansion

Proper belt tension can minimize wear and extend service life. Another best practice is to keep the conveyor system at lower temperatures whenever possible. This is to reduce thermal expansion when stainless steel in mesh belts are exposed to high temperatures continuously. It can be a problem in situations where tolerances are very fine. Thermal expansion can be minimized by choosing belt alloys carefully.

Abbott’s Industrial Furnace Experience and Expertise

The Abbott Furnace Company has been designing and producing advanced and reliable industrial furnaces for more than 35 years. There are currently almost one thousand Abbott furnaces working in various facilities operated by private companies and government agencies like the U.S. Department of Defense, and they are all supported by a team of dedicated service technicians.

We can provide belt-fed furnaces with both reactive and inert atmospheres controlled by our proprietary S.M.A.R.T. monitoring and analytics system, and we ensure that our equipment complies with industry standards like SAE International’s AMS 2750E. We can match your application with the appropriate furnace geometry and features including belt width, the number and length of heating zones, and the atmosphere control system.

Contact Abbott Today

If you are looking for a furnace supplier that understands your industry and is committed to your success, we can assist you and answer any questions you may have about conveyor technologies to keep your furnace systems running smoothly. You can call us at (814) 781-6355, or fill out our online form.

Roller Belts for Furnaces

Another common method of conveyance is the roller belt. Roller belts feature a series of independently turning tubular rollers assembled in a fixed frame. This creates a smooth and continuous surface for parts to travel across.

Advantages of Roller Belts

Installing a furnace with a roller system can be a faster process than installing a mesh belt because most of the assembly is done at the furnace manufacturer’s facility. Pre-assembled sections can then be transported to the customer’s site and easily moved into place. They are then welded and bolted together by factory trained professionals.

Good for Heavy Loading Applications

Furnace rollers are most commonly used when processes require moving heavy materials because the rollers turn independently with low friction. Rollers allow trays and individual items to move smoothly and without being pushed along by another tray or object.

Unlike a mesh belt, rollers are not susceptible to cumulative pressure or stress because they operate independently. This means they are a good choice for moving heavy components over longer distances.

Rollers Offer Flexibility

Depending on the application, rollers can operate as a unit with each moving at the same speed and direction, or they can be run individually. Because it’s possible for individual rollers to turn at different speeds, in reverse, or even stopped or set to oscillate, it’s possible to create very precise patterns of movement through the furnace such as moving more slowly through a muffle section, or pausing in a steam chamber for a set period of time.

Rollers also have long service lives because they remain in the same temperature zone at all times, which means that they are not subjected to the thermal cycling that can cause premature wear in belts or other conveyor systems.

Choosing the Right Conveyor for Your Furnace

When it comes to selecting the best conveyor system, your application is the determining factor. Both mesh belts and rollers have advantages in certain situations. There really is no one-size-fits-all conveyance system for all applications.

Considerations for Mesh Belts vs. Rollers

When making the decision between a mesh belt conveyor furnace and one that comes with rollers, manufacturers and metallurgical facilities should consider the following:

- Application: What type of thermal processes will the material undergo, including temperatures and time elapsed in the furnace?

- Materials: What are the characteristics of the material that will be conveyed, such as part weight and dimensions?

- Footprint: How much space is available for the furnace and its conveyor system?

- Operation: What volume of parts must be processed and at what speed?

- Environment: Will environmental factors like high humidity, corrosive gases, or flammable atmospheres influence the decision?

- Cost: What is the budget for the furnace?

Operating Temperature of Your Furnace

The operating temperature of the furnace is an important consideration. Temperature is a particular concern for mesh belts, which can become brittle over time when exposed to high temperatures. Stress-relief procedures are recommended when furnaces operate at temperatures below 1650 degrees Fahrenheit. This usually involves maintaining the belt at a temperature 50 degrees Fahrenheit higher than the usual operating temperature for an hour. When furnaces operate at higher temperatures, stress relief should be performed for at least two hours.

Process Requirements of the Belt

Process requirements are often the deciding factor when choosing a furnace conveyor system. For instance, if processes require material to be moved at a constant conveyor speed, a system that relies on mesh belts could provide a relatively simple and inexpensive solution. On the other hand, if your operations require heavy loads or a combination of different speeds of movement through the furnace, a roller system may be more appropriate.

Account for Belt Tension and Thermal Expansion

Proper belt tension can minimize wear and extend service life. Another best practice is to keep the conveyor system at lower temperatures whenever possible. This is to reduce thermal expansion when stainless steel in mesh belts are exposed to high temperatures continuously. It can be a problem in situations where tolerances are very fine. Thermal expansion can be minimized by choosing belt alloys carefully.

Abbott’s Industrial Furnace Experience and Expertise

The Abbott Furnace Company has been designing and producing advanced and reliable industrial furnaces for more than 35 years. There are currently almost one thousand Abbott furnaces working in various facilities operated by private companies and government agencies like the U.S. Department of Defense, and they are all supported by a team of dedicated service technicians.

We can provide belt-fed furnaces with both reactive and inert atmospheres controlled by our proprietary S.M.A.R.T. monitoring and analytics system, and we ensure that our equipment complies with industry standards like SAE International’s AMS 2750E. We can match your application with the appropriate furnace geometry and features including belt width, the number and length of heating zones, and the atmosphere control system.

Contact Abbott Today

If you are looking for a furnace supplier that understands your industry and is committed to your success, we can assist you and answer any questions you may have about conveyor technologies to keep your furnace systems running smoothly. You can call us at (814) 781-6355, or fill out our online form.