Abbott Furnace Company manufactures continuous belt sintering furnaces used in the powder metal industry. Sintering is a heat treatment applied to a powder compact in order to impart strength and integrity. The temperature used for sintering is below the melting point of the major constituent of the powdered metal material.

Abbott Furnace Company designs and builds custom sintering furnaces around our clients’ manufacturing needs – the time, temperature, and atmosphere requirements for their specific product manufacturing process.

Sintering Furnace Features

Alloy or Ceramic Muffle

- Muffle to help direct, control, and reduce atmosphere flow.

- Incorporates a silicon carbide muffle.

- This ceramic muffle is guaranteed for 5 years if used under recommended operating procedures.

Gas or Electric Heating

- We offer both types of furnace heating, depending on your needs.

- Our gas heating systems incorporate Abbott’s “pulse-fire” technology.

Rapid Cooling System (VariCool)

- Optional VariCool advanced cooling system combines both atmosphere cooling and conventional water-jacketed cooling technology into one convenient unit.

- The unit can be added when the need for sinter hardening is present in a process.

Atmosphere Moisturizing

- An optional moisturizing system can be used to alter sintering furnace dew points to ensure proper sintering conditions.

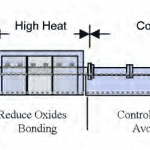

Quality Delube Processor (Q.D.P.)

- Custom designed reaction/combustion chambers and regulated atmosphere control, combined with our under-hearth heating system, assures that the delube process is completed efficiently and effectively.

High-Temperature Ceramic Belt Furnace

- High-Temperature Ceramic Belt Furnace technology propelled conventional continuous belt sintering from the 2100ºF range up to a temperature of 2350ºF.

- Use of strong, ceramic link belt enables superior load-bearing capacity, high throughputs, and better net-to-gross heating ratio.

Monitoring & Control

- We offer computerized monitoring and control systems that may supervise several different functions including sintering furnace temperature, atmosphere flow, dew point, oxygen content, carbon control, belt speed, etc.

- Abbott Furnace utilizes a variety of systems to perform these functions.

Lubricant removal continues to be one of the most challenging steps in the production of powder metal components. As compaction technology continues to push green densities to higher levels, the removal of the lubricant from the compact becomes even more difficult.

The new Vulcan Delube System, developed by Abbott Furnace Company, addresses this need. Through precise atmosphere and temperature control, the powder metal compact is placed in the optimal environment for the extraction of the lubricants.

Existing technology is very sensitive to product size, belt loading, and lubricant content. Weight loss studies have demonstrated that the Vulcan Delube System is built with enough flexibility to allow the atmosphere and thermal profile to be adjusted to prevent the oxidation of light loads and small parts; as well as the ability to remove large amounts of lubricant from heavy loads and large products.

SINTERING FUNDAMENTALS

The production of powdered metal components can be summarized in three steps: powder preparation, compaction, and sintering.

Metal powder is first formed and blended to a desired chemical composition. During this step, a lubricant, such as wax, is added to help in the ejection of compacts from the molding press. The metal powder mixture is then put into a punch and die toolset of a molding press, and compacted to form a “green” compact.

Related Articles

A Guide to Powdered Metal in Manufacturing

Powdered metals are used for many manufacturing applications. Our guide explains what you need to know about how they’re made and put to use.

Save Time & Money with an All-in-One, Continuous Process for Soft Magnetic Composites

Soft magnetic composites drive electrification in many applications. Continuous process furnaces keep them cost-effective and efficient to manufacture.

Advances in Powder Metal Sintering Technology

Stephen L. Feldbauer, Ph.D. Abbott Furnace Company Introduction The traditional powder metal process, often referred to as “’press and sinter”, is constantly driven to change by an industry goal of entering new markets through substitution and the development of innovative products for new applications. Although much advancement has been made in tite area of compaction,