Don’t have time to read this article? Click here to watch it instead!

Automotive products made with powder metallurgy can be smaller, lighter, more dense, and more heat resistant than those made with other methods. That’s important for today’s precision vehicles and ever-growing demand for fuel efficiency in internal combustion engine vehicles and longer battery range in electric vehicles (EV). Common powder metallurgy manufacturing applications include:

- Bearings

- Gears

- AC motor stators

- Engine and transmission components

- Shock absorber parts

- Seat adjustment parts

One of the biggest challenges with this manufacturing process is removing all lubricant from green compacts, which is critical to achieving a proper sinter. Leftover lubricant leads to the formation of soot in and on parts during sintering, which impacts the strength and performance of the finished part, as well as the system it goes into.

Convective vs. Radiant Heat

The commonly accepted rule of thumb for lubricant removal is 20 minutes in a radiant heat style preheating section of a sintering furnace that’s set to temperatures that are between 1,200° F to 1,800° F. This should allow the lubricant to melt and run out of the compacts. However, at particle densities over 6.6 g/cc or higher (which is common across manufacturers), this approach becomes less and less effective. In fact, as density increases and pore size decreases, lubricant removal time increases exponentially. This creates a major bottleneck to production and is not sustainable.

Recent research by Coble, et. al. involving ethylene bis-stearamide (EBS) lubricant, which is a standard lubricant in the powder metallurgy industry, examines this traditional approach to lubricant removal and an alternative method.

The data sheet for a typical EBS lubricant product indicates a melting point of 284˚F and boiling point of 500˚F. While the melting point was able to be verified by Powel, et. al., the boiling point was not. In fact, the lubricant remained in green compacts at temperatures as high as 1011˚F, at which point the lubricant turned to carbon (i.e. soot).

The data sheet for a typical EBS lubricant product indicates a melting point of 284˚F and boiling point of 500˚F. While the melting point was able to be verified by Powel, et. al., the boiling point was not. In fact, the lubricant remained in green compacts at temperatures as high as 1011˚F, at which point the lubricant turned to carbon (i.e. soot).

The researchers concluded the optimal temperature range for removal is 350˚F to 1000˚F. The challenge is that the radiant heat used in most furnaces doesn’t penetrate the compact consistently in this range. Instead, convective heat is required.

Why is an Integrated Furnace System Better than Add-ons?

Creating a separate convection heat zone within the furnace makes it possible to heat parts evenly to the precise temperature. An internal conveyor ensures parts stay in the chamber for the correct amount of time. It’s also critical to introduce moisture to the chamber to regulate the atmosphere and facilitate breakdown of the lubricant into hydrogen and carbon monoxide. By controlling temperature, exposure time, and atmosphere in this way, soot is avoided.

In conventional furnaces, workaround solutions include installing muffle extensions to pre-heat parts, or adding nitrogen bubblers or other systems to inject moisture. However, more precise control over these variables is possible with an integrated furnace system.

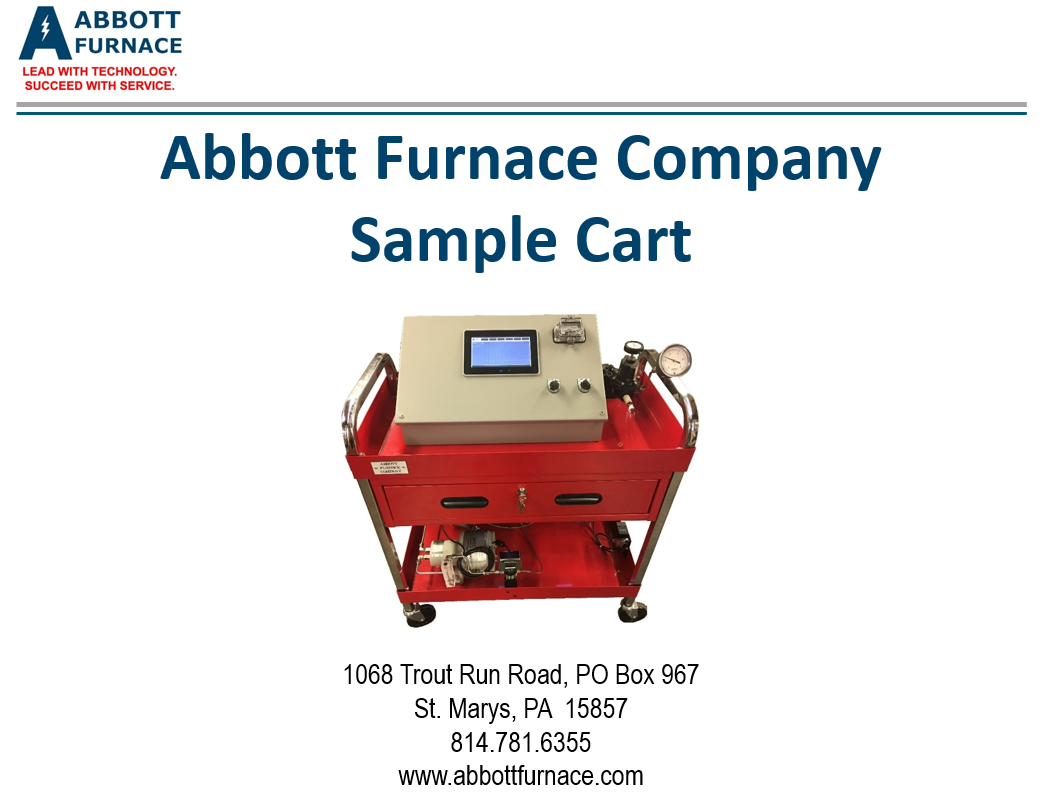

An example is Abbott’s Vulcan process, which is engineered for flexibility and complete control over temperature, time in each zone, and atmosphere flow rate and composition.

This process works with a wide range of loading configurations, part sizes and densities, so it is flexible enough to accommodate a diverse current repertoire as well as future innovations.

Watch our webinar to learn more about lubricant removal.

Demonstrated Benefits to Properties and Productivity

A great advantage of a system like this is that the equipment for convection heating, regulated conveyance, and atmospheric control are part of the furnace design, and all controls and instrumentation are integrated. This allows you to set the exact process parameters required for each product and make fine adjustments easily. It’s not “good enough” but rather “just right” every time.

Another advantage is the improved mechanical properties of powder metal parts made using the Vulcan process. That means a better overall product. For example, research has shown the following results (depending on particle density):

- Transverse rupture strength

- 18 percent increase with single stack

- 4 percent increase with double stack

- Rockwell B hardness

- 4 to 6.3 percent increase with single stack

- 6 to 5.8 percent increase with double stack

- Improved sinter indicated by rounder pores resulting from complete lubricant removal.

This system also lets manufacturers meet production priorities by single or double stacking parts as desired. For example, the research cited above indicates that compared to a conventional furnace the Vulcan process can achieve:

- Better mechanical properties at the same rate of production, or

- Comparable mechanical properties at twice the rate of production

Depending on manufacturing goals, it’s possible to increase production or improve properties as needed for each component in production.

At Abbott Furnace Co., we’re committed to providing innovative industrial furnace equipment as well as the research to back it up – please contact us to talk about your goals for lubricant removal, sintering, and product development!