The product development cycle doesn’t always follow a straight line. It starts with research and prototyping stages, followed by small-scale production; however, depending on how proof-of-concept testing and validation play out, a manufacturer may ramp up production or go back to the drawing board multiple times.

Once a final design is selected and mass produced, tweaks and revisions to the original are common.

Alternating current (AC) motor developments are an example of this iterative process. Both the materials they’re made of and the methods for working with those materials are breaking new metallurgical ground. Here’s how.

A Fertile Test Environment for AC Motor Innovations

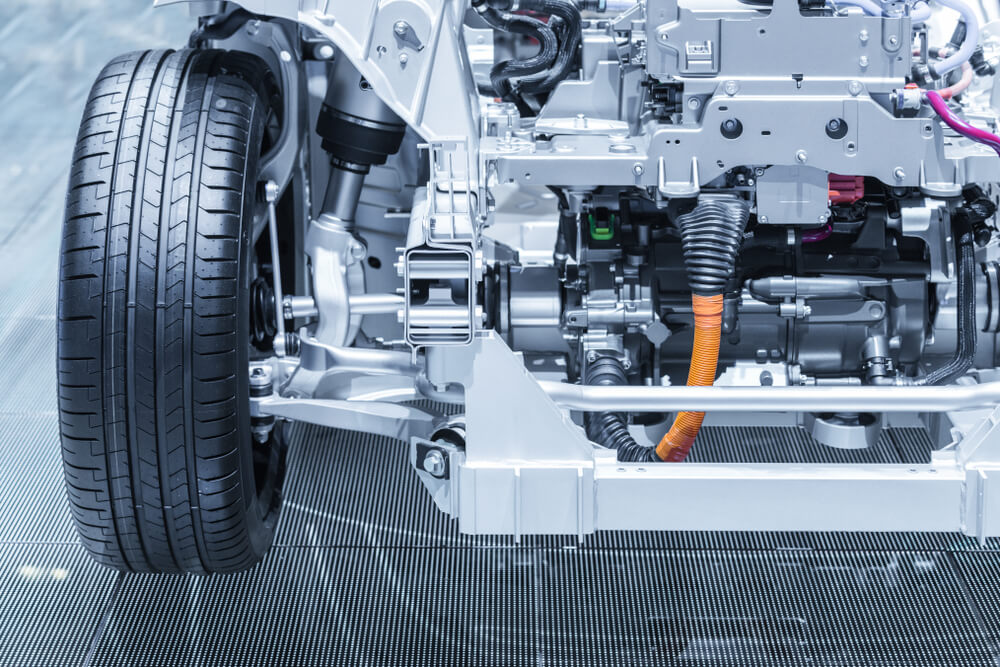

Researchers and manufacturers looking to test new designs for compact motors and better batteries often turn to small, quickly produced products such as bicycle or scooter motors, appliances, pumps, and other items. This is because they can often be redesigned multiple times and brought to market more readily than cars and trucks.

Some of these proof-of-concept applications include AC motors that power vehicle systems like windshield wipers, automatic seat or mirror adjustors, power windows and locks, and bicycle or scooter motors.

A Changing Design

An AC motor is made of a stator, which is a stationary component, and a rotor, which spins inside the stator and produces torque, which can be used to move things. In a standard motor, the stator is wrapped with a metal coil or thin laminated layers of metal. AC runs through that wrapped material and causes the push/pull motion that makes the rotor spin.

Beginning in the 1980s, soft magnetic composite materials revolutionized DC motor applications. Instead of wrapping coils or laminated material around the stator, the stator itself can be made of powder metal material that creates a magnetic field.

Recent developments in particulate materials have resulted in a powder metal material that is best suited for AC applications. This material, known as soft magnetic composite, is made of ferrosilicon particles mixed with phosphorous and a lubricant to aid in the ejection of the product from the compaction press. The composite is molded into the part shape. Then in a critical step, the lubricant must be removed from the completed part, also called the compact, through heat treatment. Finally, the piece is cured under controlled atmospheric conditions, usually with steam, nitrogen, or oxygen.

The key advantage to using a particulate material like this is that each individual particle acts as an independent layer, contributing to the magnetic field and turning the rotor faster, despite being smaller overall than a traditional stator component.

Optimizing the Furnace to the Process

Of course, this is just one way manufacturers are experimenting with new materials and methods. There are many ways to make smaller, lighter weight, and stronger components for vehicles and other applications. In many cases, one of the biggest barriers to production lies with thermal processing.

In a traditional furnace, it can be difficult to control temperature, processing time, and atmospheric conditions as tightly as necessary for an efficient process.

At Abbott Furnace Company, we have the expertise and experience to develop industrial furnaces that precisely match process requirements, such as:

- Specific temperature ranges

- Regulated belt speeds to control the time spent in each zone

- Atmospheric control by injecting gas at just the right time for curing

- Integration with robotic equipment to reduce handling and cycle times

- Computerized condition monitoring systems to track production and equipment parameters

Please contact us to learn how we can help optimize your thermal treatment processes!