Pulp and water form the basis for molded pulp and molded fiber products. Depending on the end use, different raw materials are used in the pulp recipe, and they are prepared in different ways. For example, products that will be used for food must be free of dyes and certain chemicals, while those used for packaging furniture or electronics may have less strict requirements.

Here, we’ll take a closer look at the pulping process.

Raw Materials

Pulp can be made from many types of organic fibers including:

- Post-consumer use materials – used paper, paperboard, cardboard, Kraft papers

- Organic materials – wheat straw, bamboo, sugarcane and sorghum stalks (i.e., bagasse pulp)

- Virgin materials – new, previously unused material such as wood chips or shavings

It’s also possible to reuse scraps trimmed from finished pieces by adding them directly to the pulp mixer. However, each time pulp materials are reused, the fibers become shorter and weaker, so this approach may not be appropriate for every application.

In general, raw materials are first chopped, shredded, ground, or otherwise physically broken down and then mixed and heated with water and other chemicals to create a moldable slurry. Depending on how the finished product will be used, coloring agents or waterproofing and oil-proofing additives can be included in the mixture.

Mechanical Pulping

There are two primary methods of turning raw materials into fibrous pulp for molding: mechanical and chemical.

There are two primary methods of turning raw materials into fibrous pulp for molding: mechanical and chemical.

In mechanical pulping, materials are blended in a machine called a pulper, which is not unlike a large household blender or food processor with a workbowl and blade. Warm or hot water is added to make the fibers swell and break up into pulp. The resulting mixture has the consistency of runny oatmeal. It’s then drained or filtered to remove any plastics, metal (e.g., staples), and inks.

Mechanical pulping has a higher yield than chemical pulping because it doesn’t break the raw material down as much as chemical processes do. It is also energy intensive.

Chemical Pulping

Chemical pulping is often used with virgin wood raw materials as well as straw materials like wheat, rice, or bagasse. A major goal of chemical pulping virgin wood fibers is removing lignin, which binds the individual fibers together, compromises strength of the finished product, and causes yellowing over time. Removing lignin leads to a stronger and nicer looking product, though overall pulp yields are lower when lignin is removed.

There are two methods of chemical pulping and both involve cooking the pulp in a large tank called a digester. In the sulfite process, ground wood is cooked in a combination of sulfurous acid and limestone. This method is used less often due to environmental concerns. In the more commonly used sulfite or kraft process, the ground wood is cooked in highly alkaline sodium sulfide, resulting in very strong finished product.

Pulp may then be washed and bleached to make it whiter, but this depends on its intended use. It’s also important to consider how consumers and retailers perceive the environmental impact of a bleached product compared to an unbleached one.

Regardless of the pulping method, it can be further processed to thicken the mixture, often by pressing or with a centrifuge. This is also an effective way to recover some process water for reuse.

Molding and Drying Pulp Products

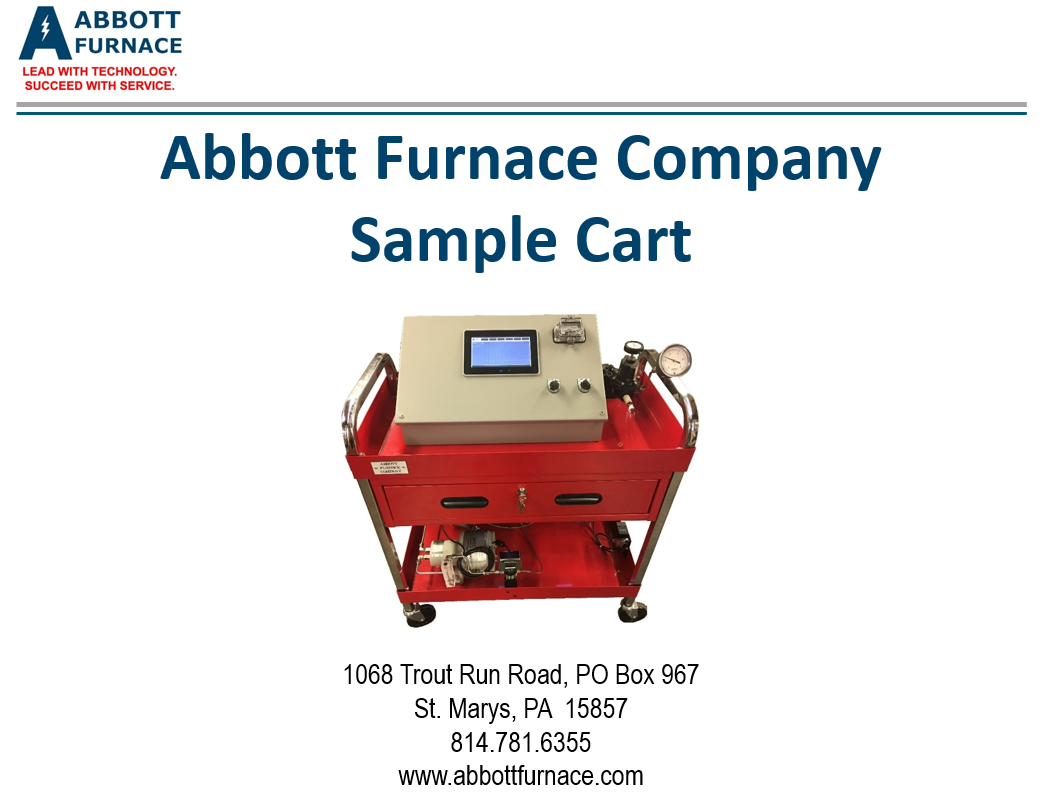

Once the pulp slurry recipe is prepared, it is placed in a tank to be used with transfer molds or thermoforming molds. Molded products pressed with transfer molds are then placed in a specialized drying oven to help excess moisture evaporate.

Once the pulp slurry recipe is prepared, it is placed in a tank to be used with transfer molds or thermoforming molds. Molded products pressed with transfer molds are then placed in a specialized drying oven to help excess moisture evaporate.

You can learn more about the entire process of molded pulp production on our website, or contact Abbott Furnace Company to discuss your pulp drying needs – we’re always here to help!