Molded pulp, sometimes called molded fiber, is a versatile multi-tasker in the world of packaging materials. Manufacturers across industries use it to protect many types of products, including:

- Form-fitting protective packaging for glass bottles and other delicate or fragile items

- Single-use food bowls and clamshells or box inserts for medical products

- Horticultural products, plant pots, etc.

- Protective pieces for furniture, electronics, etc.

- Trays to organize sets of items inside larger boxes (e.g., personal care products, “kitted” sets of products)

- Bottles for detergents and other liquids (often lined to be waterproof)

And then there’s the well-known egg carton, where it all began. “The first patent for a machine for making pulp products was registered in 1903 by Martin L. Keyes … molded pulp was soon after used as packaging for eggs, which was designed and produced by the Canadian inventor Joseph Coyle,” note Didone, et al. in this article.

And then there’s the well-known egg carton, where it all began. “The first patent for a machine for making pulp products was registered in 1903 by Martin L. Keyes … molded pulp was soon after used as packaging for eggs, which was designed and produced by the Canadian inventor Joseph Coyle,” note Didone, et al. in this article.

Why Choose Molded Pulp?

Molded pulp packaging is a cost-effective, earth-friendly alternative to plastic, especially expanded polystyrene (EPS), and even corrugated board. Its value is clear to manufacturers, consumers, and retailers for many reasons, such as:

Lower production costs. Molded pulp is most often made from recycled materials: post-consumer and post-industrial use paper and cardboard as well as stalks/straw leftover from producing wheat and sugar (e.g., bagasse from sugarcane and sorghum). Prices for these raw materials are not tied to the price of petroleum or resins and have historically stayed low and stable.

Versatile design and manufacturing. Because it starts as a liquid slurry of fibers and water, this material can be formed into a range of shapes and designed to custom-fit items with great precision. In addition, the rotary mold equipment used in forming is mechanically simple and mold tooling can be swapped out easily for quick changeover.

Efficient packaging. Finished packaging products, such as drink carrier trays or corner protectors, usually nest for storage and transport, which means they take up less space in warehouses and factories. Because pieces fit products precisely, die-cutting and assembly are eliminated.

Sustainability and renewability. As a recyclable product made from recycled materials, molded pulp exists in a loop. Even scraps and trimmings of dried pulp packaging can be mixed into a new batch of pulp slurry. Types 1 and 2 molded pulp products are 100 percent recyclable and compostable.

Safe for food applications. Molded pulp is safe for food applications, and it’s even compatible with wet or greasy foods or liquids when manufactured water- and oil-proof additives.

Consumer approval. Today’s consumers notice and demand sustainable packaging, exerting considerable purchase power. According to Forbes, “packaging is more than a mere container. It is a recurring opportunity to hold a brand in your hand. Packaging represents more consumer daily impressions than any other communications medium. Consider packaging as content marketing. Package design communicates.”

Retailer preferences. Growing numbers of large retailers are backing sustainable and green packaging. Manufacturers can make their products more attractive to retailers by adopting sustainable packaging materials like molded pulp. It also aids in branding/rebranding a manufacturer as environmentally conscious.

Effectiveness. Molded pulp packaging performs just as well as vacuum-formed plastic or corrugated pieces and excels against vibration. Pulp packages can be designed in complex, 3D shapes to protect and house items better than a traditional box with foam “peanuts” or crumpled paper filler. Because pulp is not rigid, it does not damage delicate products, nor will it crumble or crack over time.

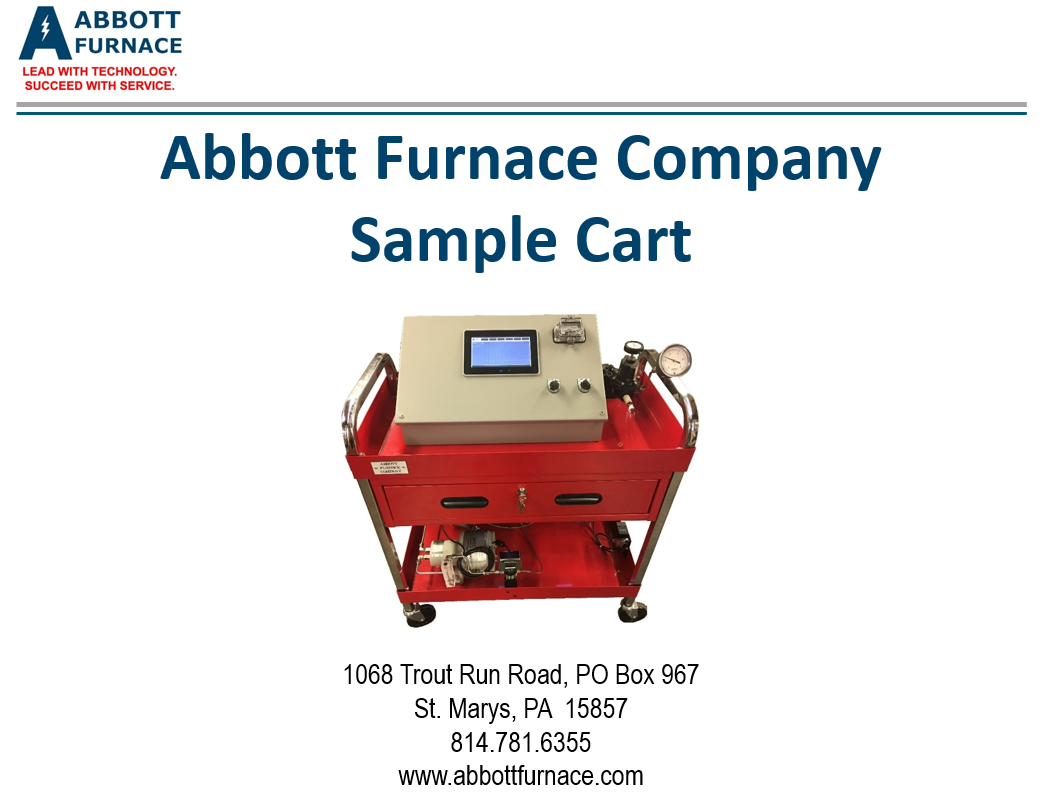

Contact Abbott Furnace Company

If you are new to manufacturing molded pulp or looking to optimize your existing process, Abbott Furnace Company can help. We design and manufacture pulp-drying ovens with continuous mesh belt conveyance, precise temperature and atmosphere controls, and real-time monitoring so you achieve high throughput and high quality. Please contact us to learn more!