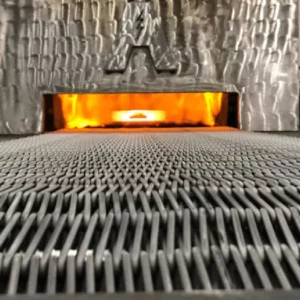

ISO/IEC 17025:2017 ACCREDITATION RENEWAL COMPLETE

We are pleased to announce that as a continued commitment to our valued customers, Abbott Furnace Company has recently completed the necessary steps to maintain accreditation to ISO/IEC 17025:2017. This accreditation allows Abbott Furnace to continue providing accredited calibration services to our many customers requiring this level of service to satisfy their automotive quality requirements. During