Abbott Furnace featured in October issue of FFJournal

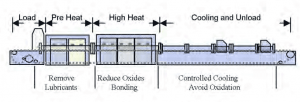

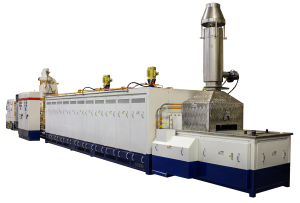

FFJournal Senior Editor, Lynn Stanley authored a piece entitled “Impossible Mission Force” about Abbott’s partnership with The ExOne Co., a leading designer, and builder of binder jet 3D printing technology, and Ford Motor Co. to develop a continuous belt furnace that could successfully sinter binder jet 3D printed aluminum 6061 and demonstrate the equipment’s ability to